Project Date: Nov. 17, 2015

Intro

As part of the numerical methods course in second year, we were given a second open ended project in which the goal was to conduct a parametric study in groups of 4 to solve an engineering problem using ANSYS AIM (it was in beta back then).

My group and I originally wanted to optimize the heat transfer of a brake disc and look at the impact of heat at the effectiveness of braking, however we were made aware of the fact that a good study in this would involve a dynamic model, which was not possible using ANSYS AIM. As such, the group settled to optimize a desktop CPU heat sink.

Model Validation and Mesh Study

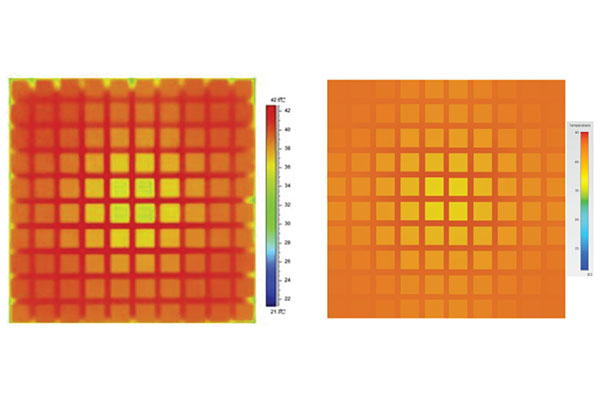

To begin, the paper “An impingement heat sink module design problem in determining simultaneously the optimal non-uniform fin widths and heights” by Huang and Chen was followed to create and validate a fluid-thermal model of a heat sink in ANSYS AIM. Once the model had been validated, a mesh study was conducted to check the sensitivity to the selected mesh. This allowed for a mesh size to be selected to optimize for the trade off between accuracy and computation time. It should be noted that the simulations were run on a quarter model of the heat sink to reduce the computation time. Symmetry wall conditions were used to ensure model accuracy.

Results

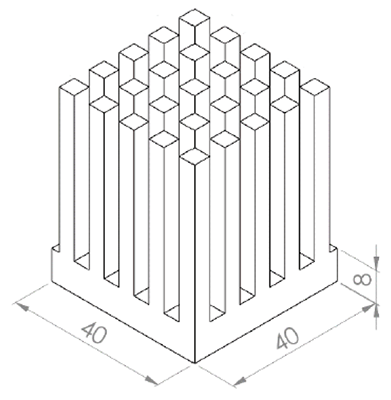

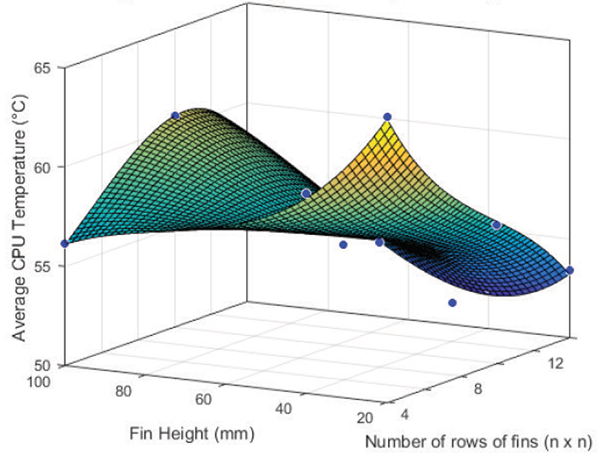

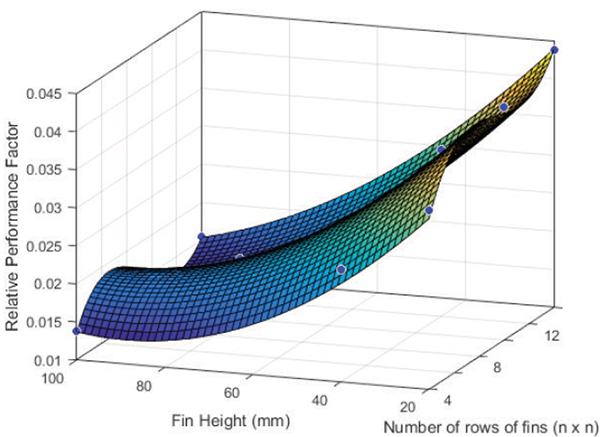

Having validated the model and determined the mesh size, parametric studies were conducted to see how the number of fins columns/rows and the fin height affected the average CPU temperature and the performance factor. The performance factor was chosen to equal the inverse of the heat sink material cost multiplied by the average CPU temperature. It was found that the average temperature increases with increasing fin height after a certain fin height. This was found to be because of the fact that the geometry interferes with the air flow after a certain point. As well, the number of rows/columns in the heat sink had an interesting downward trend for the average CPU temperature with an inflection point. After analyzing the streamlines in ANSYS, the infection point was found to be because of the air flow setup with the particular geometry. For the performance factor, it was found that the performance factor decreased with the fin height and the performance factor increased with increasing rows/columns in the heat sink.

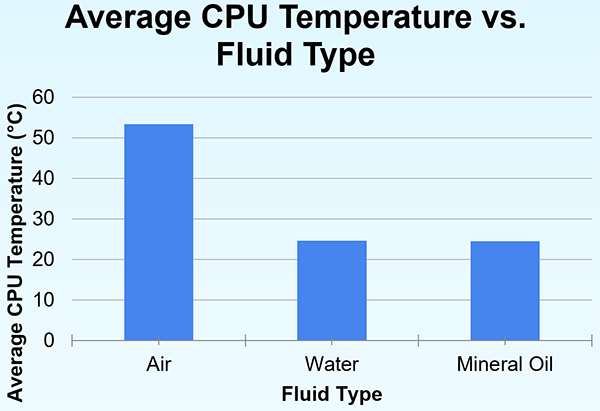

In addition to the above, a study was conducted to see how changing the fluid to water or mineral oil would affect the average CPU temperature.

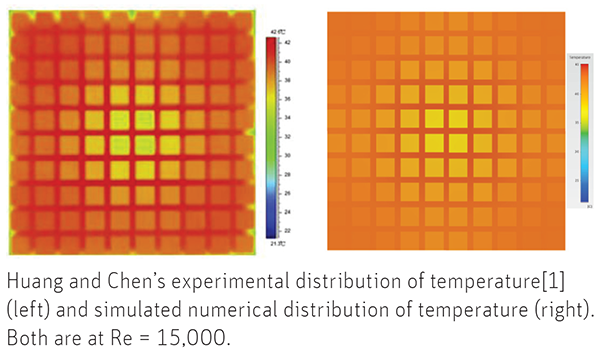

Quarter of optimized heatsink design.

CPU temperature optimization vs. fin height and number of fins.

Relative Performance Factor (considers material cost) vs. fin height and number of fins.

CPU temperature vs. fluid type for optimized design.

My Role

My role during this project was to model the heat sink in ANSYS AIM and to run the simulations used to produce the parametric study results.

Credits

This project was completed with my group members Baraa Hamodi, Hammad Mirza, Dhruv Sharma, Umer Kamran, and Oriane Magnin.