Project Date: Dec. 1, 2013

Intro

During our first semester at university, we were given an open ended project to be completed in groups of 4 in which we had to design a mechatronic system of our choice. There were a few constraints such as the design must use Lego Mindstorms NXT, three motors, three different type of sensors, etc.

My group and I decided to build a smart vending machine, which would be able to sense its environment using an ultrasonic sensor. Using the information from the ultrasonic sensor, the vending machine would determine if there were people around, allowing it to turn on/off based on surrounding traffic. Based on our preliminary research, we found that awareness was a feature missing from vending machines at the time, meaning that they would have to stay on 24/7 to maximize chances of sales, which are primarily made by attracting customers through product staging and seeming operational. A 24/7 operation time for a vending machine seems unnecessary and is likely to waste quite a bit of energy, as such we decided to pursue this project. Also, it seemed to meed the project constraints.

My Role

My role during this project mainly consisted of the mechanical design and assembly. A vending machine consists of two main mechanical subsystems (cash handling, and product delivery) allowing the two to be designed separately and integrated at the end.

Cash Handling System

For the cash handling system, a simplification that was made was the fact that the accepted currency was different colored poker chips representing different values. This allowed the cash handling system to be a color sensor equipped to a rotating poker chip holder at the end of a slotted ramp. The poker chips would get queued on the slotted ramp and once the sensor was ready, the poker chip would role on to the rotating holder. Once the color sensor had processed the “coin,” the holder would rotate and the coin would fall into the coin deposit. The main drawbacks of this design was the amount of time it took to process a payment. It should be noted that it was fairly easy to get this functioning due to the simplicity of the design.

Product Delivery System

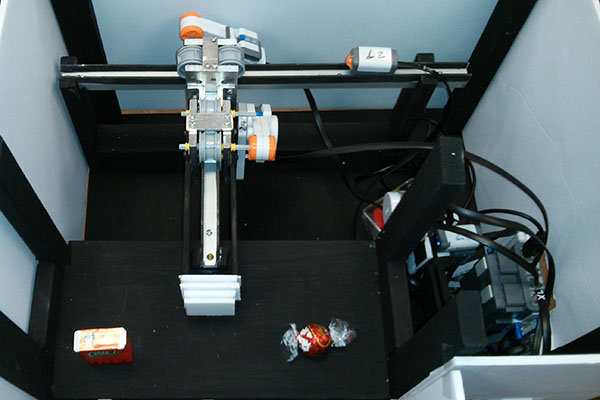

For the product delivery, a couple of designs were considered. The first design that was considered is the one that is common place in the vending machine industry, which is basically a motorized spiral. The second design that was considered and chosen was a gantry based system to push out the requested objects. The main reasons for this was the fact that we only had 3 motors to work with, one of which was already being used to process payments. We wanted our design to be scalable to more than 2 products, which meant we had to go with the latter. The main drawbacks of the current gantry is that it can only supply quantity 1 of each product. To fix this problem, one solution is to add a vertical cylinder in which more product falls down as one is pushed out.

Problems Faced

Quite a few problems were faced in the design and manufacture of the gantry system as it was my first time designing a gantry and had only heard about it a week prior from my TA. To begin, the common components used in a gantry were not available to me causing me to improvise. For example, two U channels were used to make a H track for wheels we found in the Lego box and seemed to surprisingly fit. To continue, once assembled it was found that the wheels tended to slip on the H track. To fix this, we tried various tapes available in the student machine shop and settled at hockey grip tape as it seemed to have the best results.

Conclusion

Overall, this was a great learning experience. Not only did I learn to design a system I had previously no experience with, I gained my first exposure to quite a few machines in the machine shop such as the mill, band saw, and drill press.

Credits

This project was completed with my group members Darshil Parikh, Pruthviraj Atodaria, and Jalaj Sheth.